Cobots, or collaborative robots, help make workplaces safer by handling hazardous or repetitive tasks, reducing workplace injuries, and boosting productivity. Designed to work alongside people, they allow employees to focus on more rewarding roles, enhancing efficiency without replacing jobs.

Will robots take over my job?

This question gets asked a lot, especially with the advancements in automation. Cobots have been infiltrating the workplace, but with good reason. The last two years have shown a need for employees to be relieved of strenuous job tasks – step in automation. Cobots have become a normal part of the workforce but operate with influence from an individual. The interfaces used to program a cobot are made simpler so that programming skills are not a must. This also helps reduce time and costs associated with using one cobot for various tasks since there is much flexibility.

Are cobots safe?

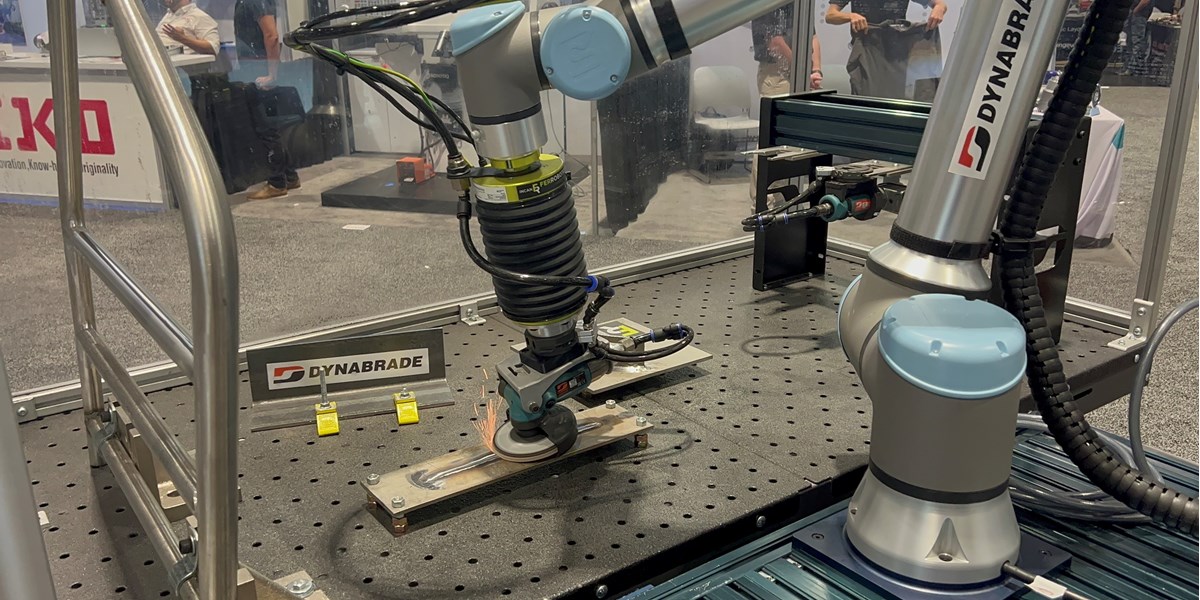

Cobots are as safe as you make them and their environment for their particular application. For example, if the end of arm tooling (EOAT) is a gripper that is picking up boxes, the system is inherently safe and shouldn't require any additional safety measures besides what is already built into the robot – the force sensors that detect bumping into somebody. If the EOAT is an angle grinder, now the system is not inherently safe. Even if the robot detected a crash into somebody, the angle grinder is still dangerous. The system now would require some additional safety measures such as a light curtain or a fence.

What is the lifespan of a cobot?

The lifespan of the cobot depends heavily on the amount it is used in the application. Is it used 24 hours a day, 7 days a week or is it used one shift a day, 5 days a week? The Fanuc CRX that Autobrade uses claims that it can be used for 8 years straight without any maintenance on the robot whatsoever. Universal Robots has claimed they have robots in the field running for 5+ years without any parts being changed out. One thing that can be certain is that the productivity gain will outweigh the cost of the robot over its lifespan. Robots can be used to increase production, reduce errors, and cut costs.

Cobots are not here to take over your job

Cobots are here to make your job less strenuous and provide a better working environment. The goal of Autobrade's automation solutions is to remove employees from dirty, dull, and dangerous jobs. These jobs can be hazardous or unsanitary. Another positive of having a cobot implemented is that it can take over tedious and highly repetitive work so employees are able to do more rewarding work. This greatly reduces workplace injuries since the more dangerous tasks are being taken over by cobots. An employee's value can increase with the knowledge and skills gained since they are relieved of those monotonous and dangerous tasks. With the introduction of cobots, there will be a demand for operators of these robots. There will always be a need for a human workforce to work alongside cobots with all the technological advances being made. With Industry 5.0 on the horizon, the collaboration between humans and robots will profoundly impact customization in the workspace and help further the growth of job creation. Industry 5.0 puts more emphasis on humans and robots working side-by-side. The impact of humans on a job will be needed in other ways and Autobrade is excited to be part of this.