Cobots are revolutionizing manufacturing by handling dangerous, repetitive tasks, improving workplace safety. These tools boost productivity while allowing workers to focus on advanced tasks.

Implementing a cobot to work alongside humans is a growing trend in the constantly evolving manufacturing industry.

With more jobs open then people able to fill them, there becomes a need to remove employees from those dirty, dull, and dangerous jobs and move them to a safer and more advanced position.

A cobot can be programmed to do more than pick and pack.

Using power tools to alleviate strenuous and repetitive work is a task that many manufacturers are willing to have a cobot take over to prevent work injuries and overworked employees.

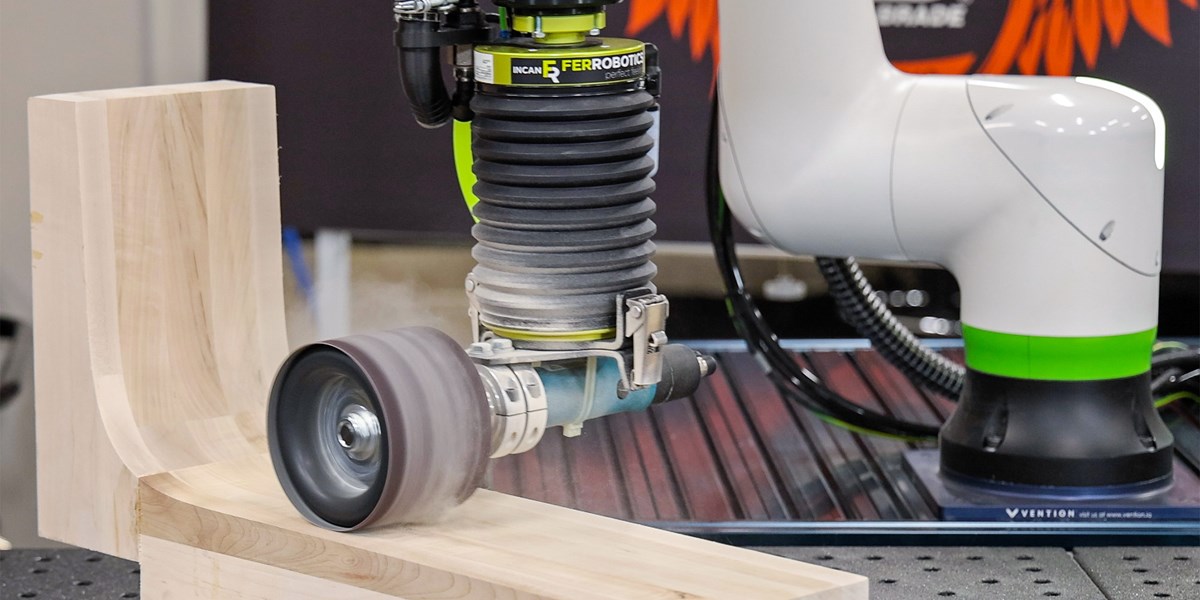

A robot end effector is described as an item that is at the end of the arm of a cobot.

Some also define it as what separates the surface from the cobot arm. An end effector can be a tool, gripper, tool changer, or other necessary attachments for the job. There could be multiple end effectors on a cobot arm, such as a contact flange and a tool. End-of-arm-tooling or EOAT is also often used to describe end effectors. Dynabrade has made a line of tools that are cobot compatible, making it easier for you to adapt your application.

We have over 40 tools that can be used on a cobot.

What makes these tools "cobot compatible" or different than others? We have removed the tool grip and changed the throttle to allow for connection to the cobot on these specific tools. We offer vacuum and non-vacuum tool options that can be attached to a cobot arm.

What connects a Dynabrade tool to a cobot?

One way is through the robotic tool kits offered that come with the Millibar manual tool changer to allow for easy tool attachment. Our tools are also compatible with the FerRobotics contact flange which takes into consideration the force needed for certain applications. We can adapt our tools to fit on any cobot.

Cobots are meant to work with humans, side by side.

Cobots are meant to work with humans, side by side. They are generally smaller (with a 20kg capability) than other industrial robots. They are easier to program, implement, maintain, and operate. As with humans, the knowledge to know more than one task is capable with a cobot. They can change out tools and on average have the capacity to learn more than 200 routines. With simpler routines, the cobot can be moving in a matter of minutes, while more complex routines can be achieved in a few hours with a decent knowledge base. If you are still unsure what end effector may be needed or where to even begin implementing an automation solution, we can help. We offer a proof of concept where the automation solution you are in need of, is brought to life through our experts. Reach out for more information and we can help automation become a reality for you.