We use cookies to give you the best experience on our site. You can find out more about the cookies we use or disable them in the cookie settings.

Software

We work closely with you to assess your needs and goals, matching you with the technology that best fits your unique requirements. Software plays a critical role in your automation setup, and our expertise ensures that you and your business are equipped to embrace the future of automation.

Easy access to automation for everyone.

Our Autonomous Adaptable Robotic System powered by MARI allows non-technical operators to drag & drop icons and flowcharts to easily program.

Place&Go

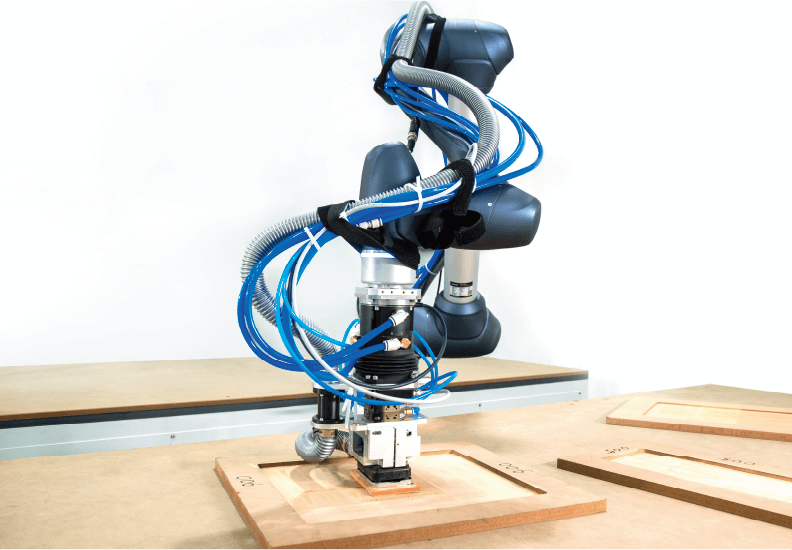

The newest evolution of automation is Place&Go. We have teamed up with MARI to offer our clients the best technology for a turnkey workstation. This Place&Go panel sanding experience allows the user to conduct automatic sanding operations for small to medium-size production runs and is an answer to the labor shortage. This technology will boost your sanding quality.

How does it work?

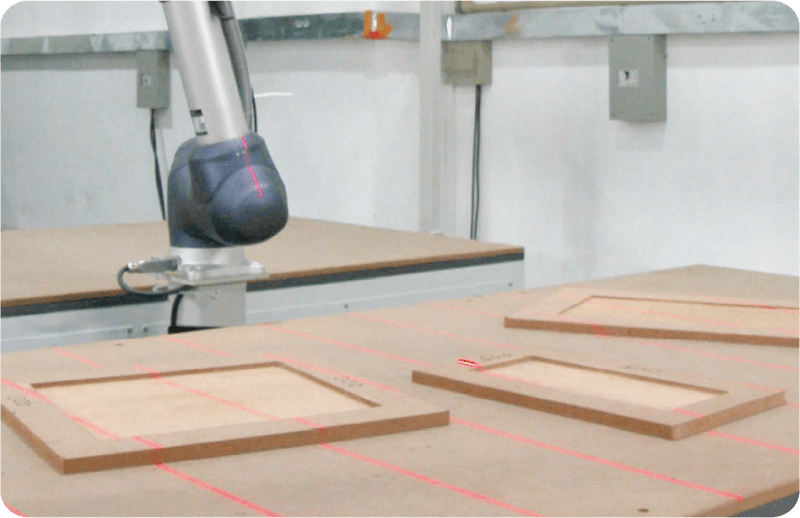

Simply place your panels on the table, and our advanced overhead 3D cameras will handle the rest. They identify the panel’s orientation and type, scanning for shape and depth. Our system then sands each panel—whether it’s a shaker or raised style—with unmatched precision and quality. Say goodbye to manual touch-ups on inside edges or corners—Autobrade’s solution ensures flawless results every time.

What is this system best used for?

A small to medium sized production run of panel sanding including raised panels, recessed panels, and flat panels. This technology is built with simplicity in mind allowing your sanding operations to be hassle-free.

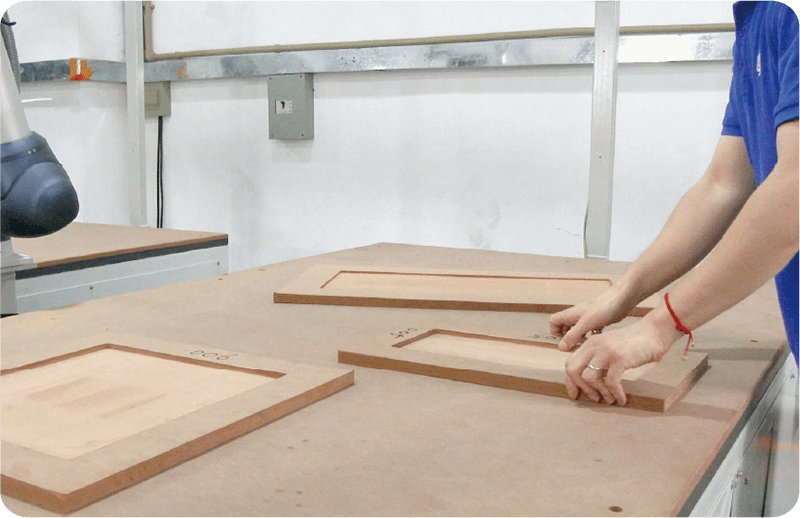

- User-friendly: Anyone can operate the station with ease with only minimal training.

- Maximized Efficiency: The whole sanding process only takes around 1-2 minutes per panel.

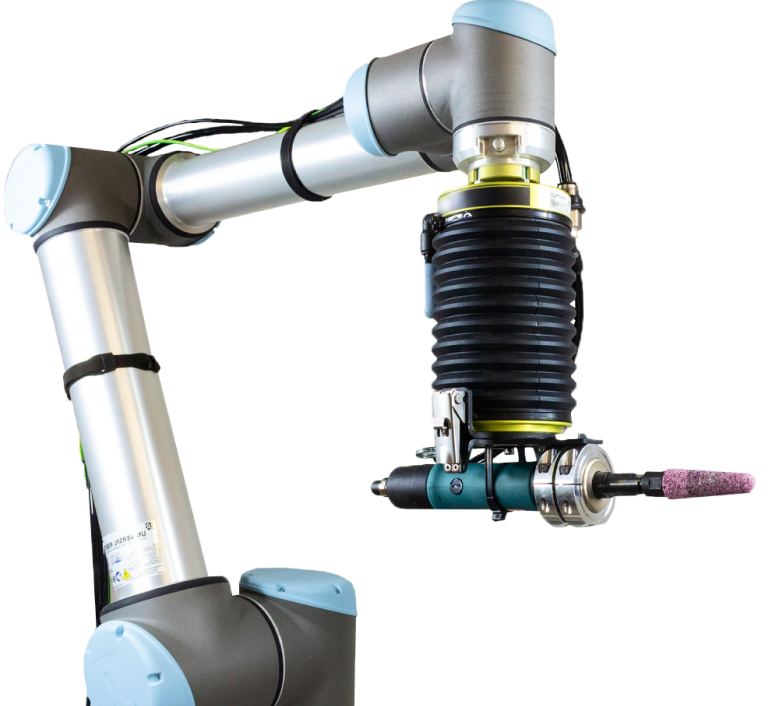

- Precision Force Control: Active force control will intelligently apply the abrasive pressure to the panel, imitating the sensitivity of a human operator.

- Laser-Based 3D Vision: High accuracy and fast laser-based structured light for 3D precision.

- Automatic Tool Changing: Square and orbital sanders can be used for multi-level surfaces, even small internal corners.

- ISO Certified Safety: The Scan & Sand system meets ISO 10218-2 and PHSR standards.

Hardware

We deliver fully customized solutions for each of our clients. From the robot to the end-of-arm tools and every accessory in between, we ensure your setup is perfectly configured from the start.

We stay up to date on the latest technology.

With continuous advancements in robotics and AI-driven software, Autobrade stays at the forefront of innovation, offering unmatched process optimization that drives consistent and reliable results. We combine these state-of-the-art technologies to provide tailored solutions that adapt to the evolving needs of industries worldwide.

Let's talk about your automation needs.

End of arm tooling is the tool or device at the very end of the cobot arm. Dynabrade makes a variety of pneumatic and electric tools for surface finishing that can fit on the end of a cobot or robot.

The Autobrade team is here to start the conversation and ask questions to find our more about your future automation project. We start our Proof of Concept process and answer any questions/concerns you have along the way.

An employee's value can increase with the knowledge and skills gained since they are relieved of monotonous and dangerous tasks. With the introduction of cobots, there will be a demand for operators of these robots. There will always be a need for a human workforce to work alongside cobots with all the technological advances being made. With Industry 5.0 on the horizon, the collaboration between humans and robots will profoundly impact customization in the workspace and help further the growth of job creation. Industry 5.0 puts more emphasis on humans and robots working side-by-side. The impact of humans on a job will be needed in other ways and Autobrade is excited to be part of this.

An automation cell is a working cell that is created around a cobot or robot. The cell usually has at least one cobot or robot, end of arm tools, and the other accessories necessary to complete the task it is programmed to do. In this cell, some complex or complicated tasks may be performed as well. Usually a human is not working next to the cobot while it is in a cell.