Taking your ideas and proving the concept a reality.

At Autobrade, we understand that every operation is unique, which is why we offer tailored consultation services both on-site and off-site to meet your specific needs. Our expert team is dedicated to providing you with the guidance and solutions necessary to optimize your surface finishing processes and automation systems.

Our on-site consultation services bring our team directly to your facility. This allows us to observe your operations firsthand, assess your current systems, and identify areas where automation and process improvements can drive efficiency and reduce costs. During an on-site consultation, our experts will:

By experiencing your operational setup in person, we can provide the most precise recommendations and implement solutions that make an immediate impact.

For companies requiring remote expertise, Autobrade offers off-site consultation services that are equally effective. Using advanced communication tools, we can connect with your team to review your current systems, analyze data, and provide detailed guidance on automating surface conditioning processes. During off-site consultations, we will:

Off-site consultation is a cost-effective and flexible option, especially for businesses seeking expert guidance without the need for immediate on-site visits.

Our goal is to optimize your operations, improve efficiency, and provide lasting solutions that enhance productivity. Whether you prefer the hands-on approach of an on-site consultation or the flexibility of remote support, Autobrade is here to help your business succeed. Reach out to schedule your consultation today!

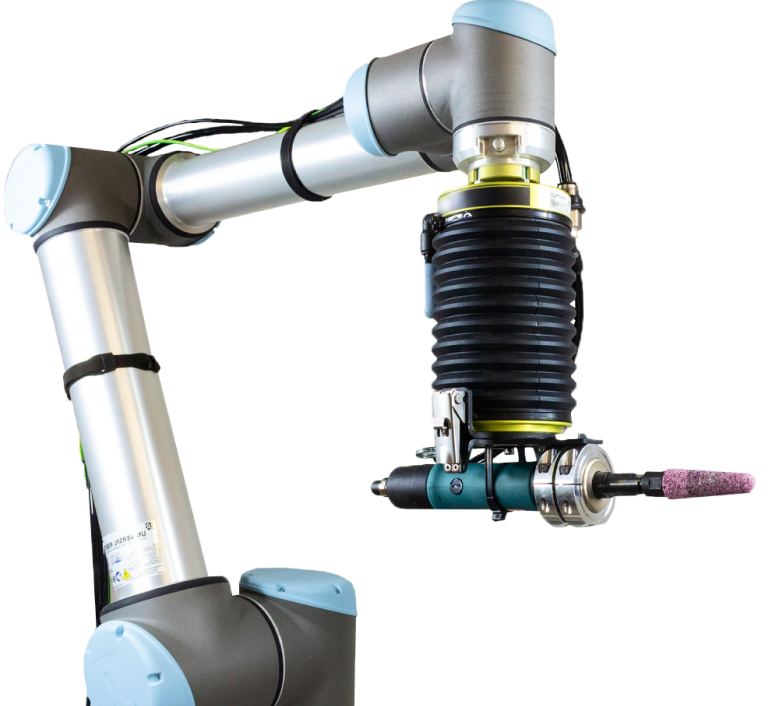

Automation comes in many forms. A manufacturer can have their welding automated, packaging and shipping could have an automation cell, and various steps in a process can be automated to save labor and time. Surface finishing applications are considered for automation since a lot of time and labor are allocated to them.

Automation helps businesses by saving money and time due to labor constraints. It also helps make employee’s jobs less strenuous and provide a better working environment. The goal of Dynabrade's automation solutions is to remove employees from dirty, dull, and dangerous jobs. These jobs can be hazardous or unsanitary. Another positive of having a cobot implemented is that it can take over tedious and highly repetitive work so employees are able to do more rewarding work. This greatly reduces workplace injuries since the more dangerous tasks are being taken over by cobots.

Our automation cells offer flexibility, consistency, efficiency, safety, and cost-effectiveness. It enables the shop to handle a variety of parts with high precision, improve productivity, and adapt to changing production requirements.

A surface finishing cell in metal fabrication is designed to automate and optimize the process of treating and finishing metal surfaces. By automating processes with Autobrade, a metal fabricator can expect consistent results and precise control over the finishing process, increased efficiency for higher throughput and reduced production time, enhanced safety, and improved quality control through integrated systems that monitor and ensure accuracy.