Taking your ideas and proving the concept a reality.

During our Proof of Concept we determine the hardware and software that would make your automation solution the most efficient. Each setup is custom to your needs.

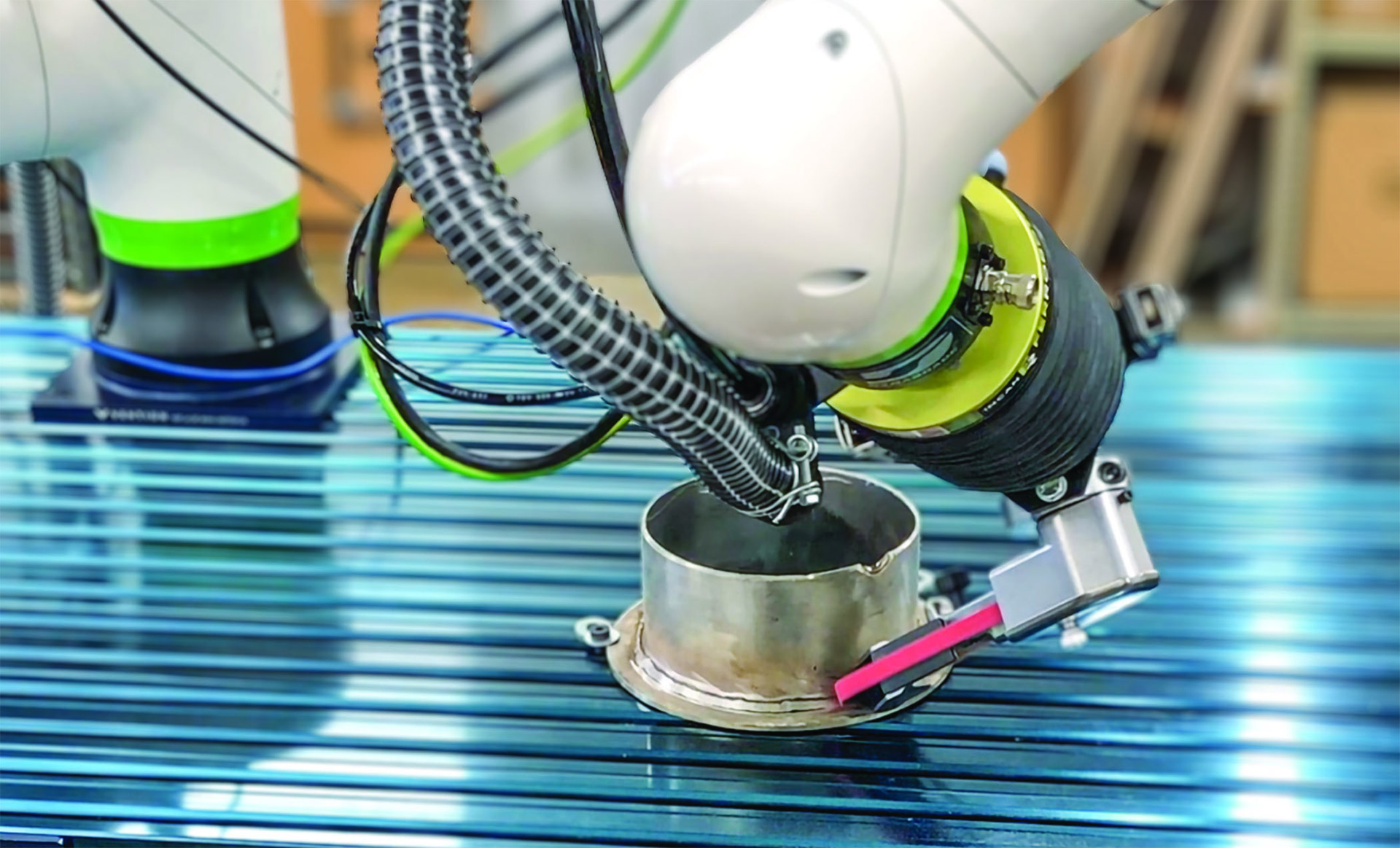

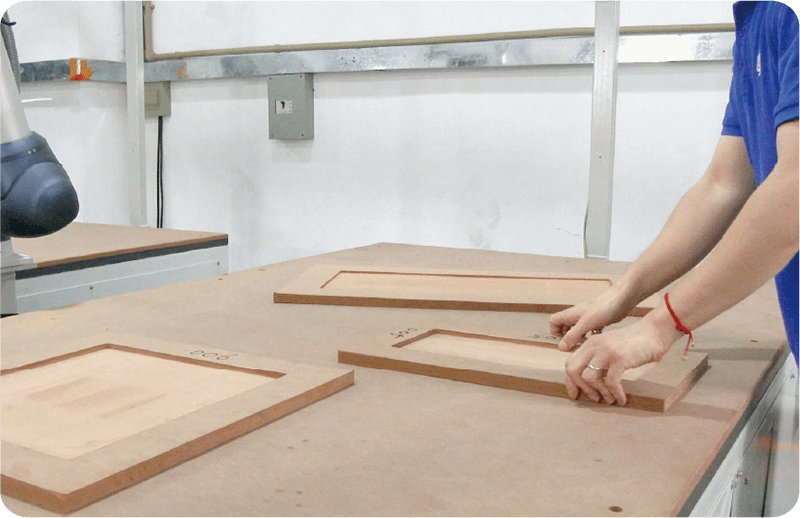

We learn and understand your process then find ways to automate it efficiently. The entire automation cell is designed to your specific needs and requirements. Panel sanding or finishing a unique metal piece – we can do it all.

Our skilled technical experts come on-site to install and deploy your automation solution. We will train and ensure your team is confident with the new process.

Our custom integration of automation cells recognizes that every business is unique, and there's no one-size-fits-all solution. We understand that each setup requires a tailored approach. Whether we design and integrate a complete automation solution or step in to finalize and optimize your existing system, we ensure your investment is fully realized and operational to meet your specific needs.

We work with high-mix manufacturers who make products to order or low-mix manufacturers who makes large volumes of a product. Let our experts find the perfect finish for your process.

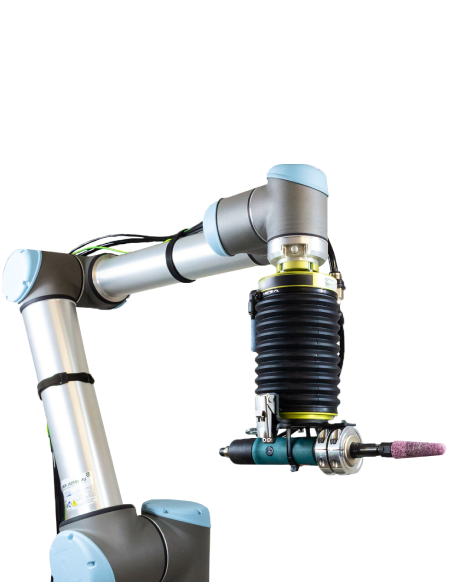

A cobot is able to work side-by-side with humans while a robot works independently. These robots are usually classified as Industrial Robots.

A cobot can relieve a human of strenuous jobs and allow that human to work alongside it. Costs associated with the process or task can be reduced since there is much more flexibility with a cobot. A cobot can work longer than the usual shift of a human in a “lights out” environment.

The lifespan of the cobot depends heavily on the amount it is used in the application. Is it used 24 hours a day, 7 days a week or is it used one shift a day, 5 days a week. The Fanuc CRX that Dynabrade uses claims that it can be used for 8 years straight without any maintenance on the robot whatsoever. Universal Robots has claimed they have robots in the field running for 5+ years without any parts being changed out. One thing that can be certain is that the productivity gain will outweigh the cost of the robot over its lifespan. Robots can be used to increase production, reduce errors, and cut costs.

Collaborative robots (cobots) offer several distinct advantages over traditional industrial robots. Cobots come equipped with advanced safety sensors and force limiters to detect and respond to human presence, minimizing the risk of injury. They feature user-friendly programming interfaces that often require little to no coding knowledge, allowing for quick setup and reconfiguration. Cobots can be easily reprogrammed and redeployed for various tasks, making them ideal for dynamic production environments. Designed to work closely with human operators, cobots assist with tasks such as assembly, packing, and material handling without the need for extensive safety barriers.