We use cookies to give you the best experience on our site. You can find out more about the cookies we use or disable them in the cookie settings.

Sanding

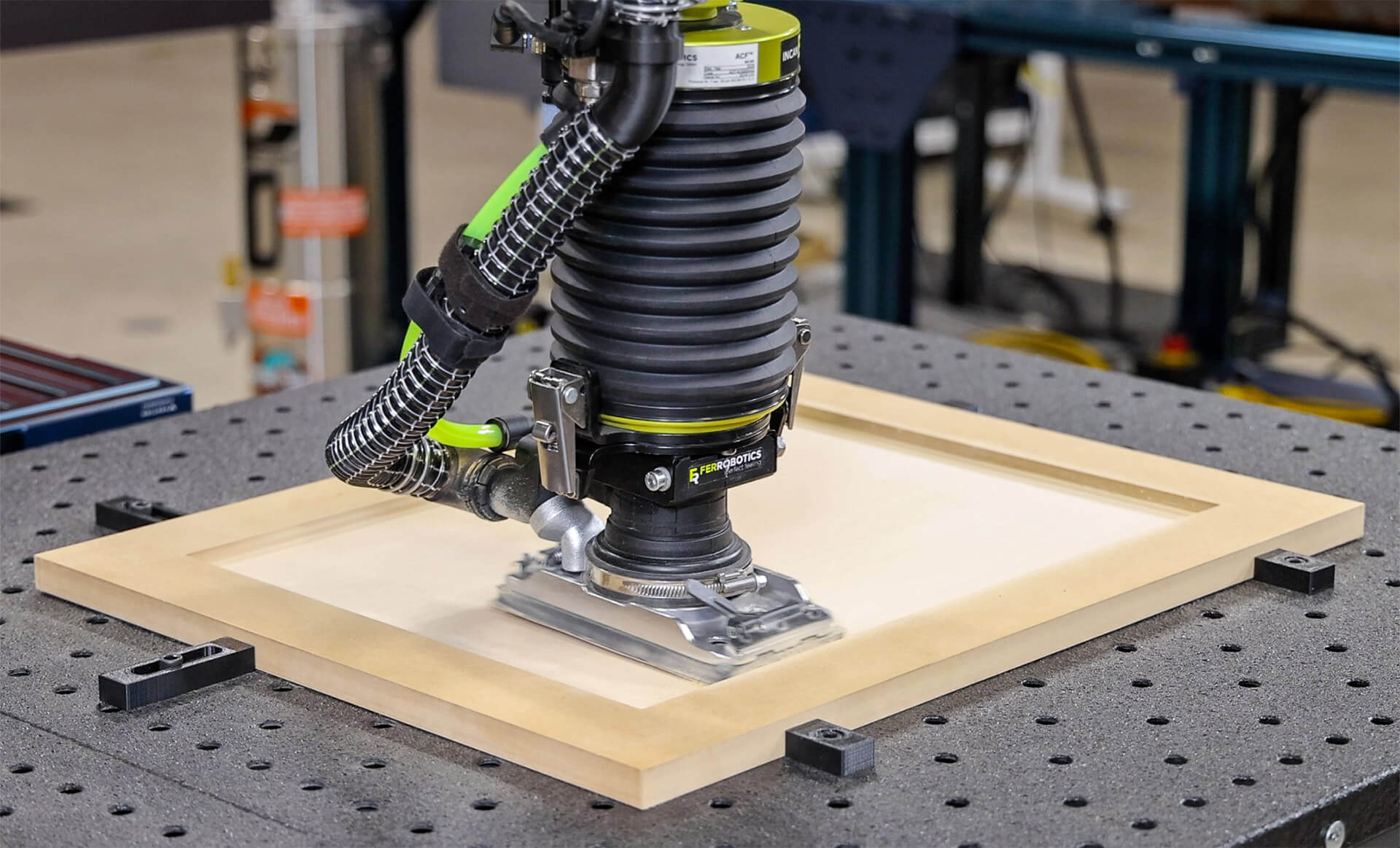

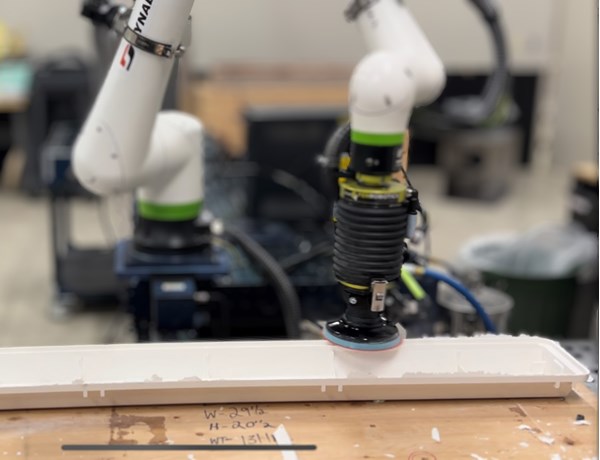

Sanding automation encompasses a few different processes depending on your industry and finish needs. General sanding, deburring, deflashing, and grinding are the most common.

Sanding

Smoothing a surface by removing unwanted impurities. This process is using different abrasives to impart a desired finish on the final product. Typically multiple abrasives are used during the sanding process, each of increasingly finer grit.

Deburring

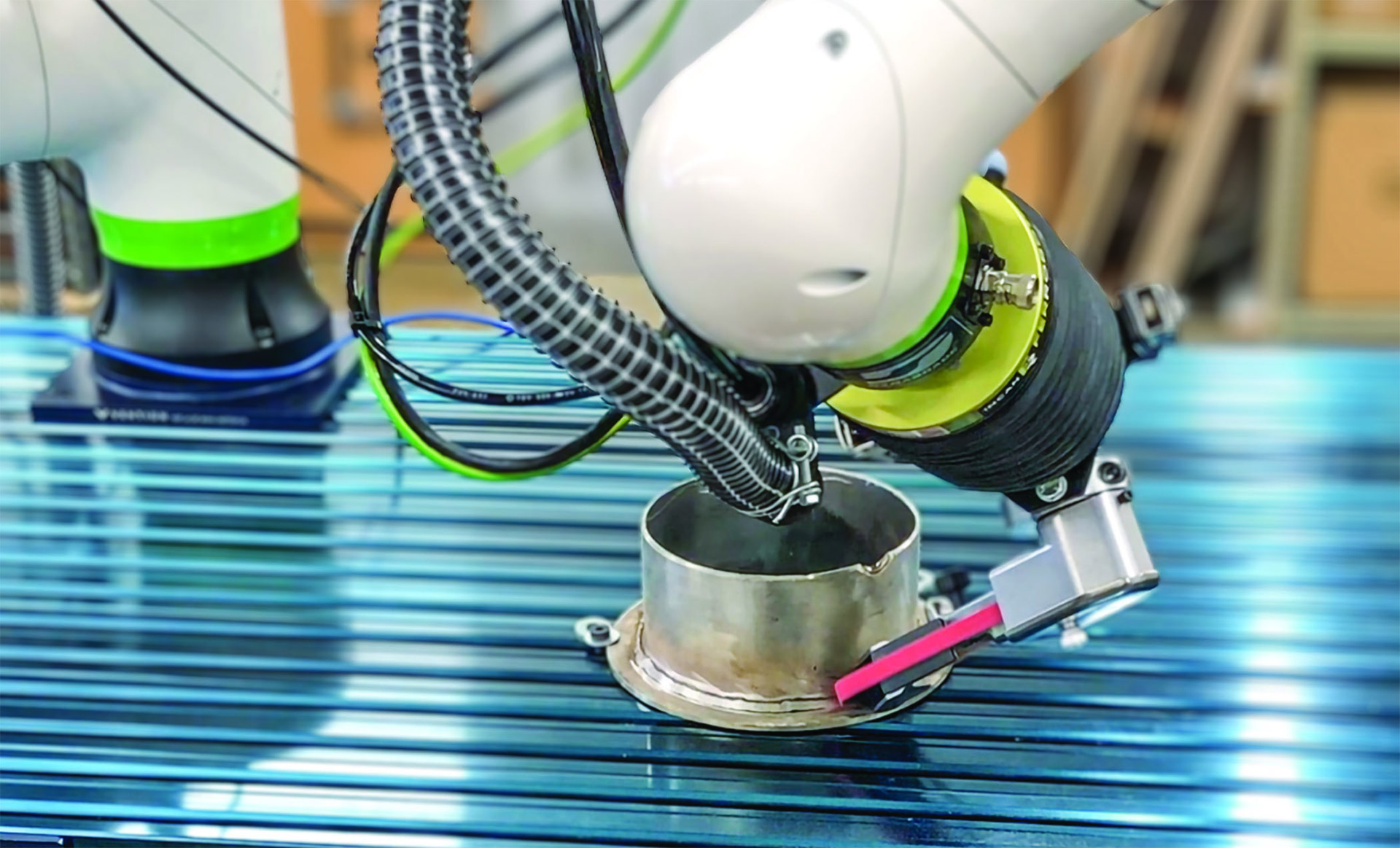

Smoothing of edges on a work piece. The edges may be sharp or have roughness to them. This process also reduces friction, makes it easier for the operator to handle, and may increase the life span of the work piece.

Deflashing

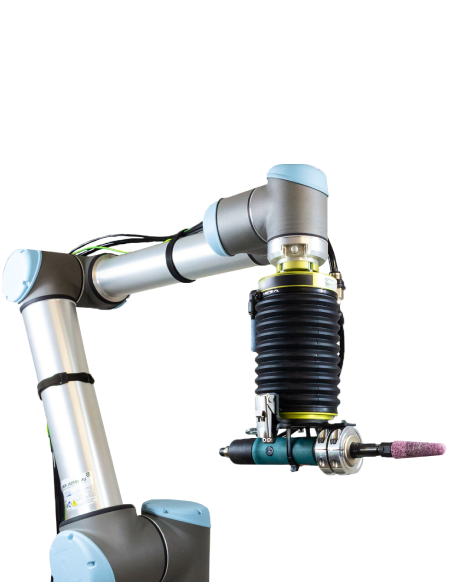

This is a process of removing the edge from a molded piece.

Our solutions

We specialize in automating surface finishing processes to enhance efficiency and precision across industries. Our comprehensive solutions cover a wide range of applications, including polishing, sanding, deburring, material removal, grinding, and more. Whether you're looking to streamline production or improve the quality of your finishes, our advanced technologies are designed to meet your unique needs and drive your business forward.

Sand better.

Surface finishing is our expertise. With over 55 years in the industry, our team is equipped to get the results your business is looking for.

Talk with our team.

End of arm tooling is the tool or device at the very end of the cobot arm. Dynabrade makes a variety of pneumatic and electric tools for surface finishing that can fit on the end of a cobot or robot.

The Autobrade team is here to start the conversation and ask questions to find our more about your future automation project. We start our Proof of Concept process and answer any questions/concerns you have along the way.

An employee's value can increase with the knowledge and skills gained since they are relieved of monotonous and dangerous tasks. With the introduction of cobots, there will be a demand for operators of these robots. There will always be a need for a human workforce to work alongside cobots with all the technological advances being made. With Industry 5.0 on the horizon, the collaboration between humans and robots will profoundly impact customization in the workspace and help further the growth of job creation. Industry 5.0 puts more emphasis on humans and robots working side-by-side. The impact of humans on a job will be needed in other ways and Autobrade is excited to be part of this.

An automation cell is a working cell that is created around a cobot or robot. The cell usually has at least one cobot or robot, end of arm tools, and the other accessories necessary to complete the task it is programmed to do. In this cell, some complex or complicated tasks may be performed as well. Usually a human is not working next to the cobot while it is in a cell.