Taking your ideas and proving the concept a reality.

We deliver investment value. More than an integrator, we are your partner in getting the right solution the first time.

Many integrators pride themselves designing and selling automation systems, but we believe in going beyond the surface to ensure that your investment delivers.

Our unique approach draws from decades of real-world industrial manufacturing experience to provide you with a customized solution designed to meet your business needs.

Autobrade was born from over 55 years of experience in the surface finishing world. We are the experts in perfecting the finish – by hand or by robot. Our technical staff is well-versed in manufacturing and ready to start your project today.

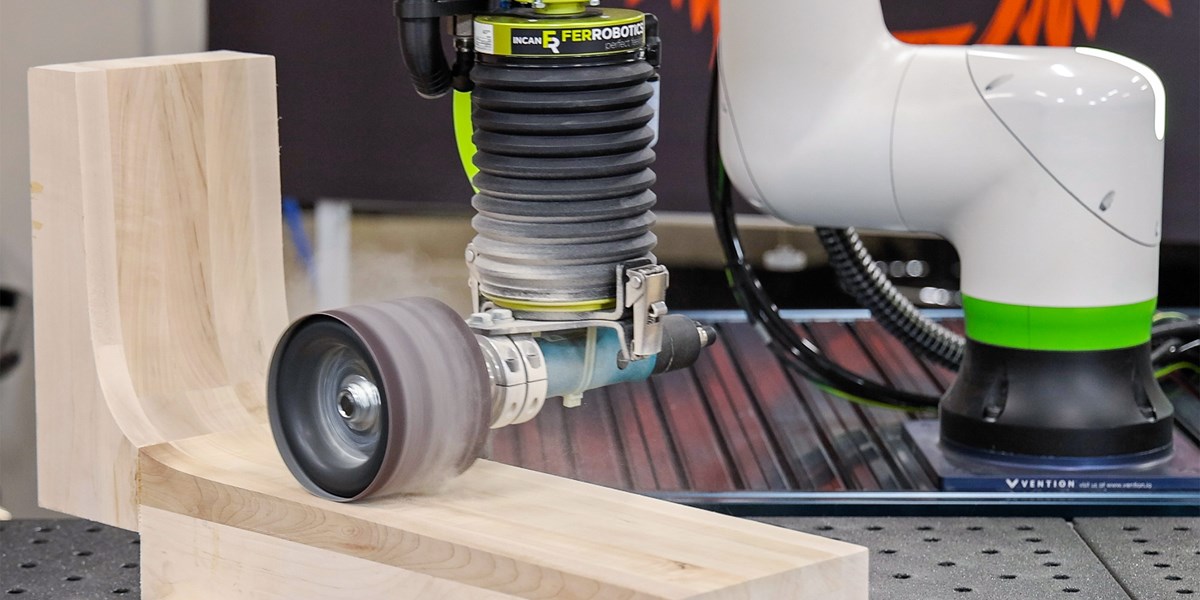

As technology advances, so does the precision and productivity of finishing tasks, allowing businesses to achieve consistent, high-quality results. By integrating cutting-edge automation, companies can reduce labor demands while optimizing performance and output.

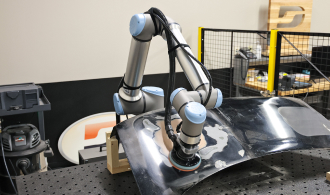

Our experts can navigate any substrate to meet your goals. Automate your surface finishing with the experts.

Contact us to get more information on making the switch to automation and how it can help.

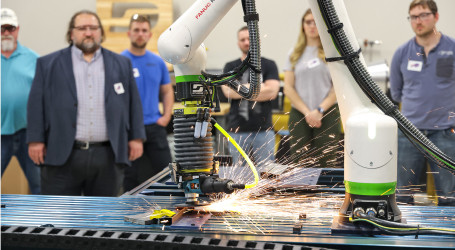

Cobots are revolutionizing manufacturing by handling dangerous, repetitive tasks, improving workplace safety. These tools boost productivity while allowing workers to focus on advanced tasks.

Cobots, or collaborative robots, help make workplaces safer by handling hazardous or repetitive tasks, reducing workplace injuries, and boosting productivity. Designed to work alongside people, they allow employees to focus on more rewarding roles, enhancing efficiency without replacing jobs.

Autobrade aims to enhance precision, efficiency, and cost-effectiveness in industrial processes. Debuting at IWF Atlanta, it will showcase its innovations and partnerships with FerRobotics and MARI.

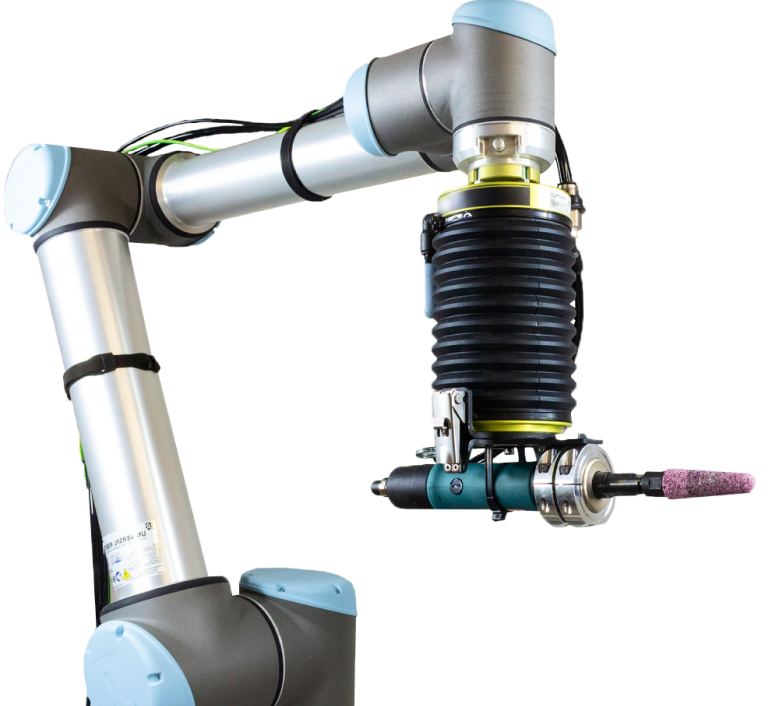

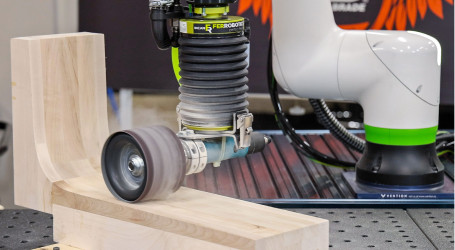

End of arm tooling is the tool or device at the very end of the cobot arm. Dynabrade makes a variety of pneumatic and electric tools for surface finishing that can fit on the end of a cobot or robot.

The Autobrade team is here to start the conversation and ask questions to find our more about your future automation project. We start our Proof of Concept process and answer any questions/concerns you have along the way.

An employee's value can increase with the knowledge and skills gained since they are relieved of monotonous and dangerous tasks. With the introduction of cobots, there will be a demand for operators of these robots. There will always be a need for a human workforce to work alongside cobots with all the technological advances being made. With Industry 5.0 on the horizon, the collaboration between humans and robots will profoundly impact customization in the workspace and help further the growth of job creation. Industry 5.0 puts more emphasis on humans and robots working side-by-side. The impact of humans on a job will be needed in other ways and Autobrade is excited to be part of this.

An automation cell is a working cell that is created around a cobot or robot. The cell usually has at least one cobot or robot, end of arm tools, and the other accessories necessary to complete the task it is programmed to do. In this cell, some complex or complicated tasks may be performed as well. Usually a human is not working next to the cobot while it is in a cell.